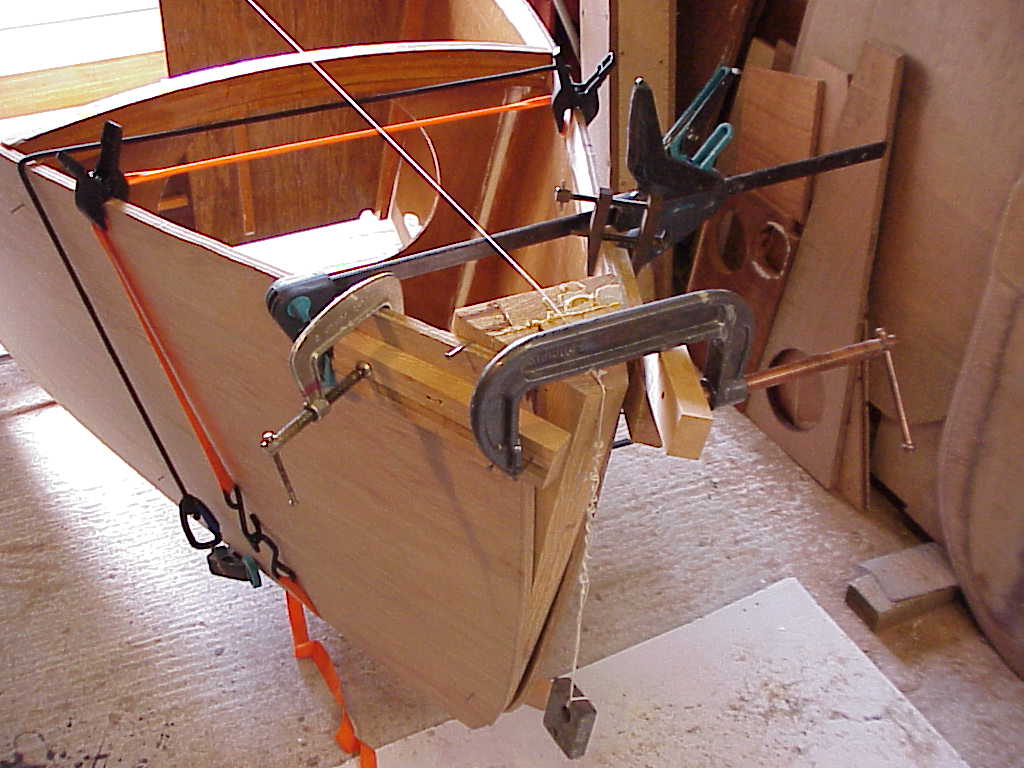

The sides are clamped on and everything is checked for fit (and modified until it does!)

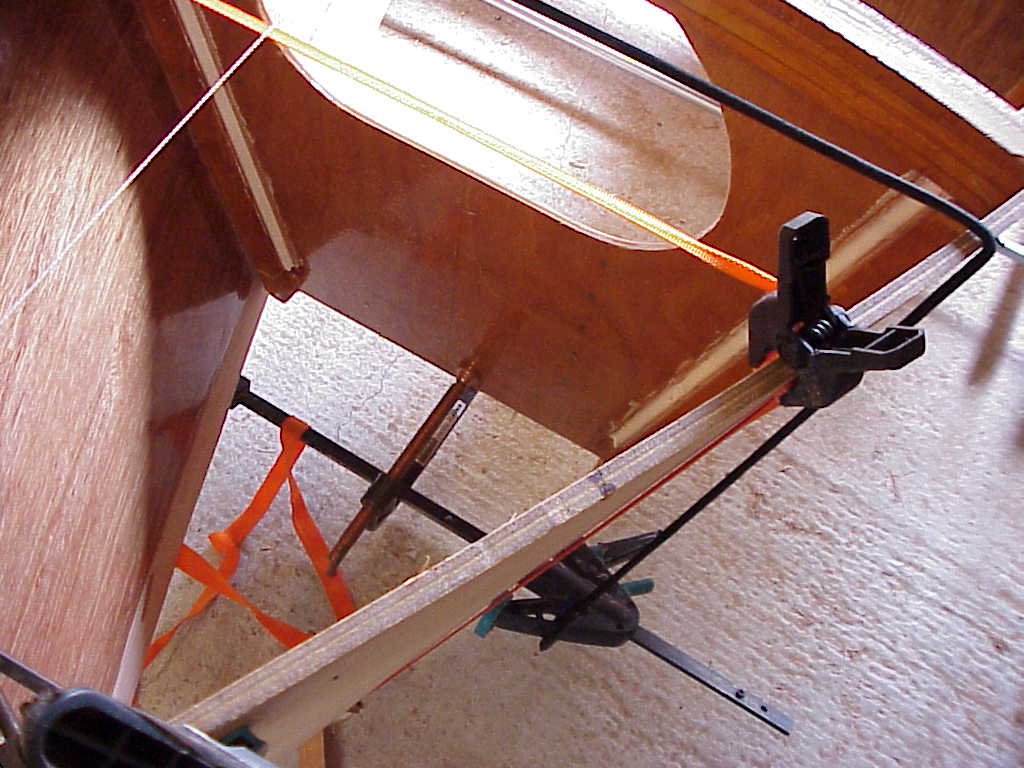

I used location pins extensively throughout the construction

These are steel nails pushed into drilled holes as dowel pins. The holes are used later for the ring nails

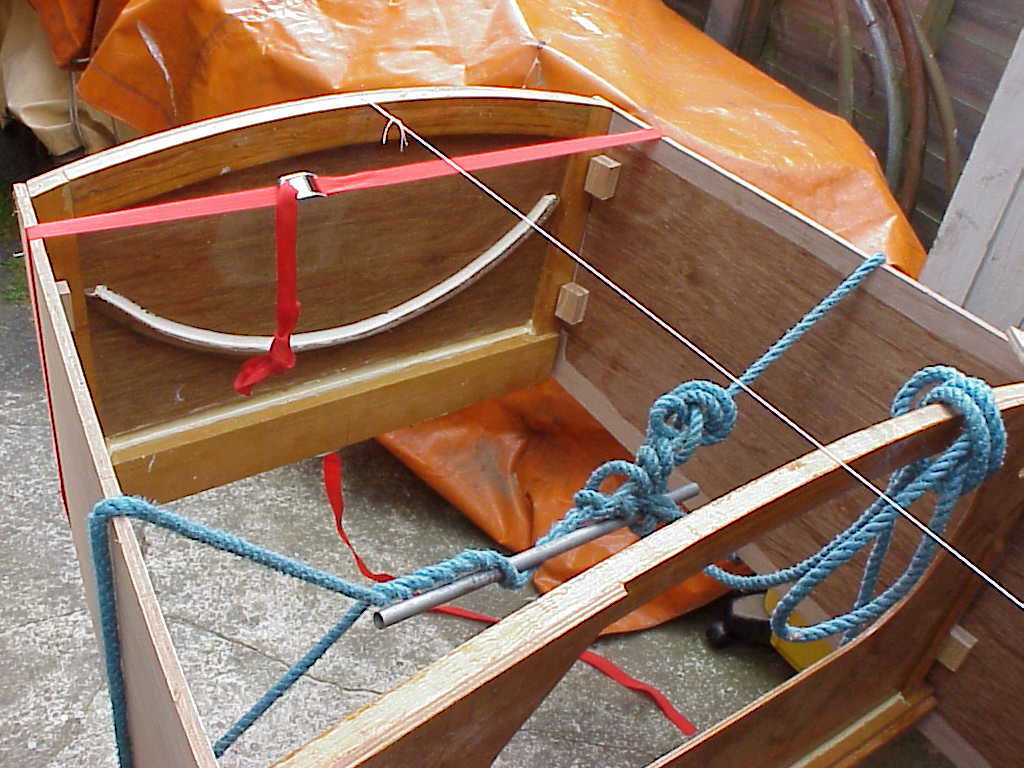

Note the location blocks glued on with a hot melt gun. These were knocked off later once the ring nails were in.

A few dozen more clamps would have helped!

Pulling in the bows was quite difficult as there is nothing to get hold of. If I was doing it again I would leave the side panels long and pull it together with studding in oversized holes in the overhang.

The string is used to line up the centrelines on each bulkhead before drilling the location pins in the stem

The floor panels and diagonal bracing will make it easy to reassemble for gluing